In the world of heavy-duty trucks, safety and reliability are paramount, and the importance of truck headlights cannot be overstated. Headlights ensure safe nighttime driving, improve visibility in adverse weather conditions, and increase the overall safety of the road. Behind these essential components, there lies a less visible but equally vital component - the aluminium board. This article delves into the crucial role of high-quality aluminium boards in truck headlight spare parts and why they are indispensable.

Durability and Longevity

Truck headlights are exposed to harsh conditions such as extreme temperatures, humidity, road debris, and vibrations. To withstand these conditions and ensure the longevity of the headlight, high-quality aluminium boards are essential. These boards are known for their corrosion resistance and durability, making them ideal for the challenging environment of a truck's front end. Manufacturers can't afford to compromise on quality, as a failure in the headlight's internal components can lead to significant safety hazards on the road.

Efficient Heat Dissipation

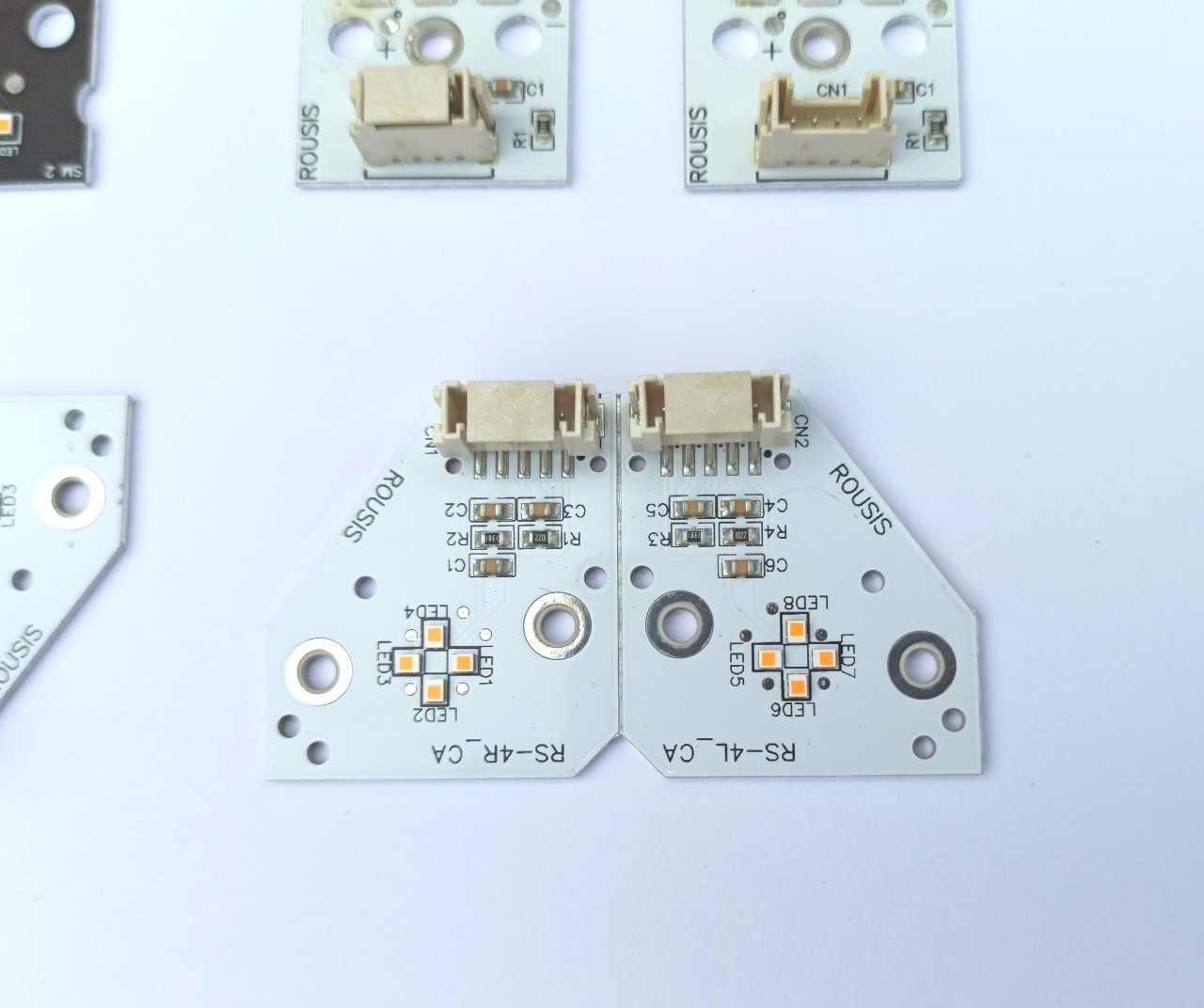

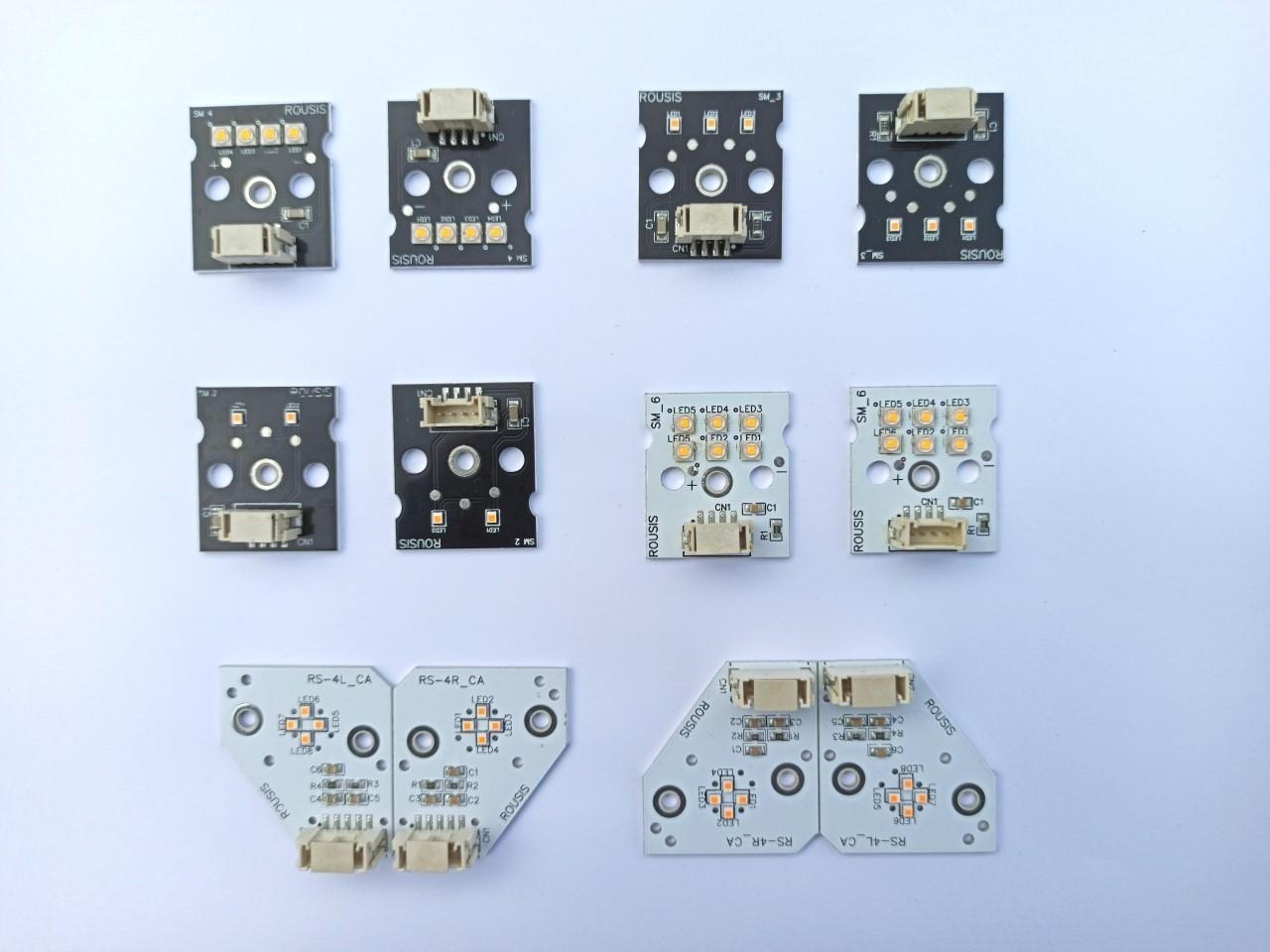

Truck headlights, particularly those using high-intensity discharge (HID) or LED technology, produce a substantial amount of heat during operation. Efficient heat dissipation is vital to prevent overheating, which can reduce the lifespan of the light source and other internal components. High-quality aluminium boards are excellent at dissipating heat, helping to maintain a stable temperature within the headlight unit. This ensures the longevity and consistent performance of the headlight.

Electrical Reliability

Aluminium boards play a crucial role in providing electrical connections for various components within the headlight, such as the bulbs, drivers, and control systems. Low-quality boards may have subpar electrical conductivity, which can lead to voltage drops, overheating, and malfunctions. To guarantee the reliability of the headlight system, high-quality aluminium boards with excellent electrical properties are essential. They offer consistent electrical connections, reducing the risk of failures or flickering headlights.

Weight Efficiency

Truck manufacturers are continually seeking ways to reduce vehicle weight to improve fuel efficiency and lower emissions. High-quality aluminium boards are lightweight and contribute to achieving this goal without sacrificing strength and durability. In contrast to traditional materials like steel, aluminium boards help optimize the overall weight of the headlight assembly while maintaining structural integrity.

Design Flexibility

Aluminium boards can be molded into various shapes and sizes, allowing for greater design flexibility in headlight construction. This enables manufacturers to create efficient and aesthetically pleasing headlight designs that cater to the specific requirements of different truck models. The versatility of aluminium boards enhances the overall appeal of truck headlights while maintaining their functional integrity.

Environmental Considerations

With growing environmental concerns, the use of high-quality aluminium boards in headlight construction aligns with sustainability goals. Aluminium is a highly recyclable material, which means that when a truck reaches the end of its lifecycle, the headlight components can be recycled, reducing the environmental impact.

Conclusion

High-quality aluminium boards are the unsung heroes in the world of truck headlight spare parts. Their durability, efficient heat dissipation, electrical reliability, weight efficiency, design flexibility, and environmental benefits are pivotal to the overall performance and safety of heavy-duty trucks. Manufacturers, as well as fleet operators, must recognize the importance of investing in top-notch aluminium boards to ensure the reliability and longevity of truck headlights, ultimately contributing to safer and more efficient transportation on our roads.

English

English  Deutsch

Deutsch  Български

Български  Italiano

Italiano  Ελληνικά

Ελληνικά